Some key considerations when designing and engineering light gauge steel frame buildings?

Designing and engineering light gauge steel frame buildings requires careful consideration of various factors to ensure structural integrity, safety, and cost-effectiveness. Here are some key considerations:

Building Codes and Regulations

Familiarize yourself with local building codes and regulations to ensure compliance. Different regions may have specific requirements for seismic, wind, and snow loads.

Site Conditions

Assess soil conditions and foundation requirements to determine the appropriate foundation design for the specific site.

Material Selection

Choose high-quality, corrosion-resistant steel that meets industry standards. Consider coatings or treatments to enhance durability and longevity.

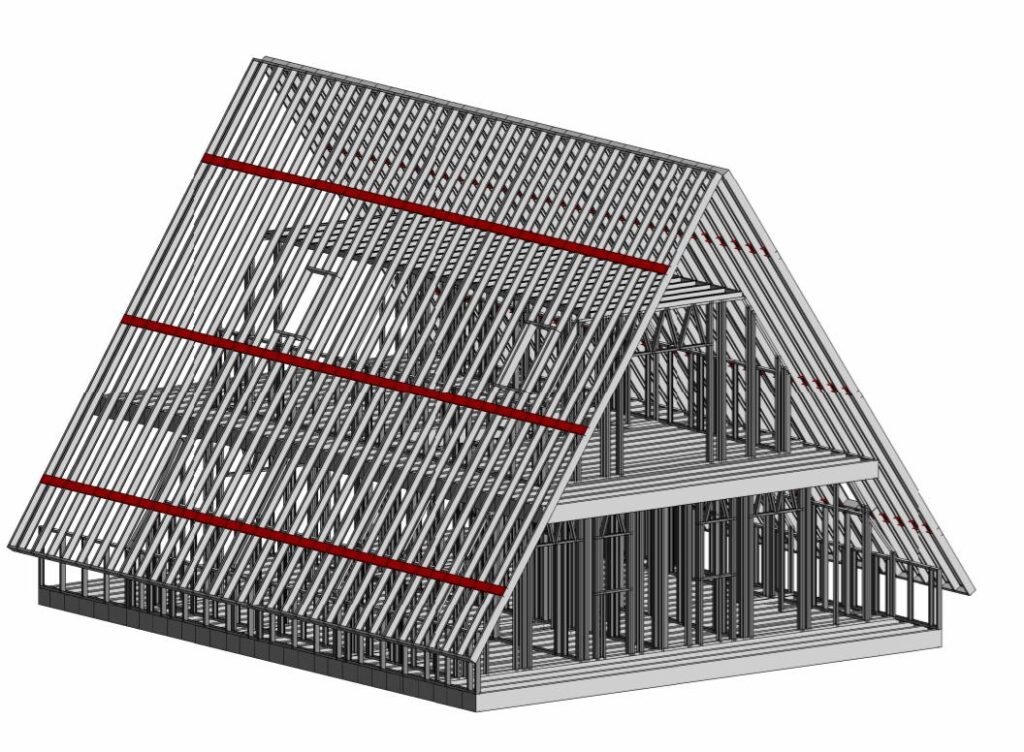

Structural Design

Collaborate with a structural engineer to design the steel frame system based on the building’s intended use and occupancy. Account for vertical and lateral loads, such as wind and seismic forces.

Connections and Fasteners

Design robust connections to ensure stability and resist lateral forces. Select appropriate fasteners, considering factors like corrosion resistance and load capacity.

Fire Resistance

Assess the fire resistance of the steel frame and incorporate fire protection measures if required by local codes. This may include fire-resistant coatings or the use of gypsum board.

Thermal Performance

Address thermal bridging issues by incorporating insulation between steel framing members. This helps enhance energy efficiency and occupant comfort.

Acoustic Performance

Consider the acoustic properties of the building, especially in residential or commercial settings. Use appropriate insulation materials and construction techniques to achieve desired soundproofing.

Construction Tolerances

Account for fabrication and construction tolerances to ensure precise assembly on-site. This helps prevent issues during erection and ensures that the final structure meets design specifications.

HVAC and Electrical Integration

Plan for the integration of HVAC systems, electrical components, and other utilities within the steel frame. Coordination during the design phase is essential to avoid conflicts during construction.

Construction Sequencing

Develop a construction sequence that optimizes efficiency and minimizes potential issues during the assembly of the steel frame. Consider transportation and handling constraints for on-site assembly.

Quality Control and Inspections

Establish a quality control plan to monitor fabrication and construction processes. Regular inspections are crucial to identify and address any deviations from the design and ensure compliance with standards.

Life Cycle Cost Analysis

Consider the long-term costs associated with maintenance, repairs, and potential renovations. Optimize the design to achieve a balance between initial construction costs and ongoing operational expenses.

Sustainability

Explore sustainable design options, such as recycled steel, and consider the environmental impact of the construction process. Implement energy-efficient features to enhance the building’s overall sustainability.

Coordination with Other Disciplines

Collaborate with architects, MEP (mechanical, electrical, plumbing) engineers, and other relevant professionals to ensure a seamless integration of all building systems.

Click here to see what are the main components of light gauge steel frame structure.https://jadrosteel.com/what-are-the-main-components-of-a-light-gauge-steel-frame/

By addressing these considerations, you can contribute to the successful design and engineering of light gauge steel frame buildings that meet performance expectations and regulatory requirements.