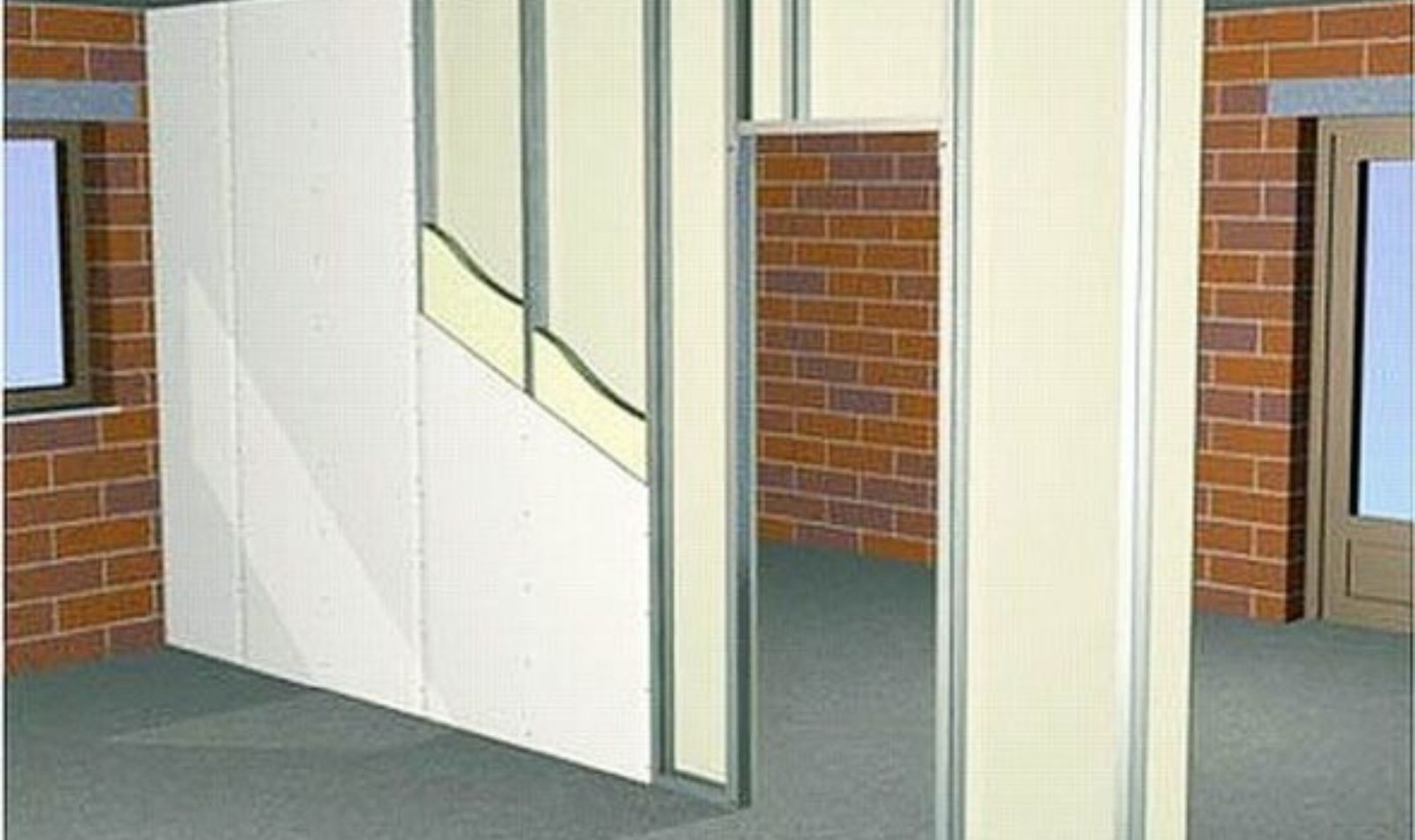

JADRO STEEL LLP is a Leading, fast growing modern Pre-fabricated Steel Building Construction company of India with a young and enterprising team consisting of Architects, Designers & Engineers providing complete end to end solution. It is the most reliable & Most Professional Prefabricated Building Manufacturers in India. We have a broad base of technical expertise in Prefabricated Steel Structures such as Warehouse Structure, Steel Structures, Portable & PUF Cabins, Prefabricated Buildings, Roofing Sheets, Modern Steel Structure houses and Commercial Buildings, PEB Factory Shed, Multi-level warehouse, Cold Storage, Hall, Aircraft Hangers, Covered Multi-Level Parking Lots, Solar Panel Support Structure, C & Z Purlin and many more fabrication items.